Your Cart is Empty

Take advantage of volume discounts on our Aluminum Trim Products:

For large orders, contact Tread-Ware for additional details and to place your bulk order.

At Tread-Ware, we understand that every project has unique requirements. Our Aluminum Diamond Plate Trims are available in custom sizes and colors, so you can choose a piece of trim that complements your specific aesthetic and functional needs. Contact us for more information.

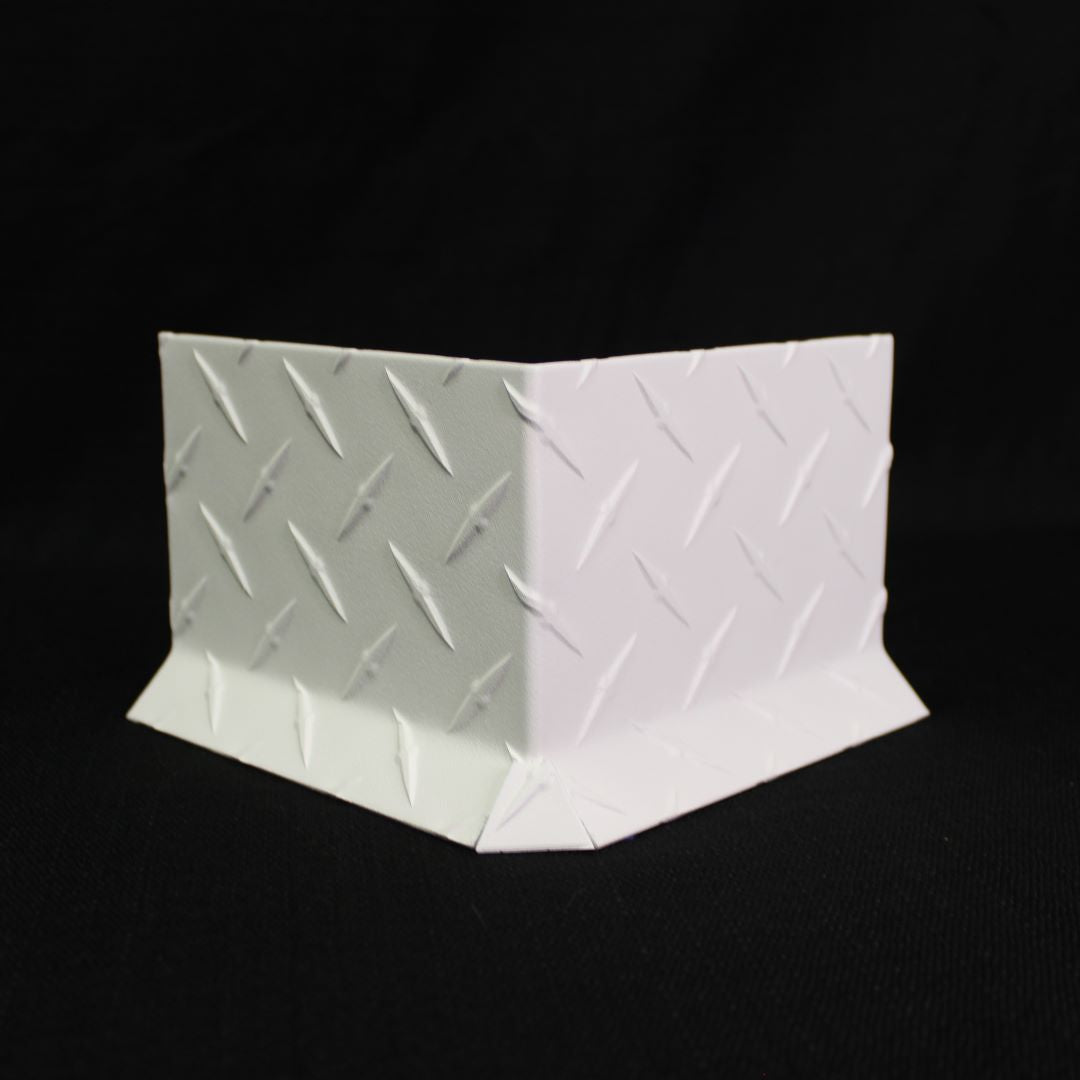

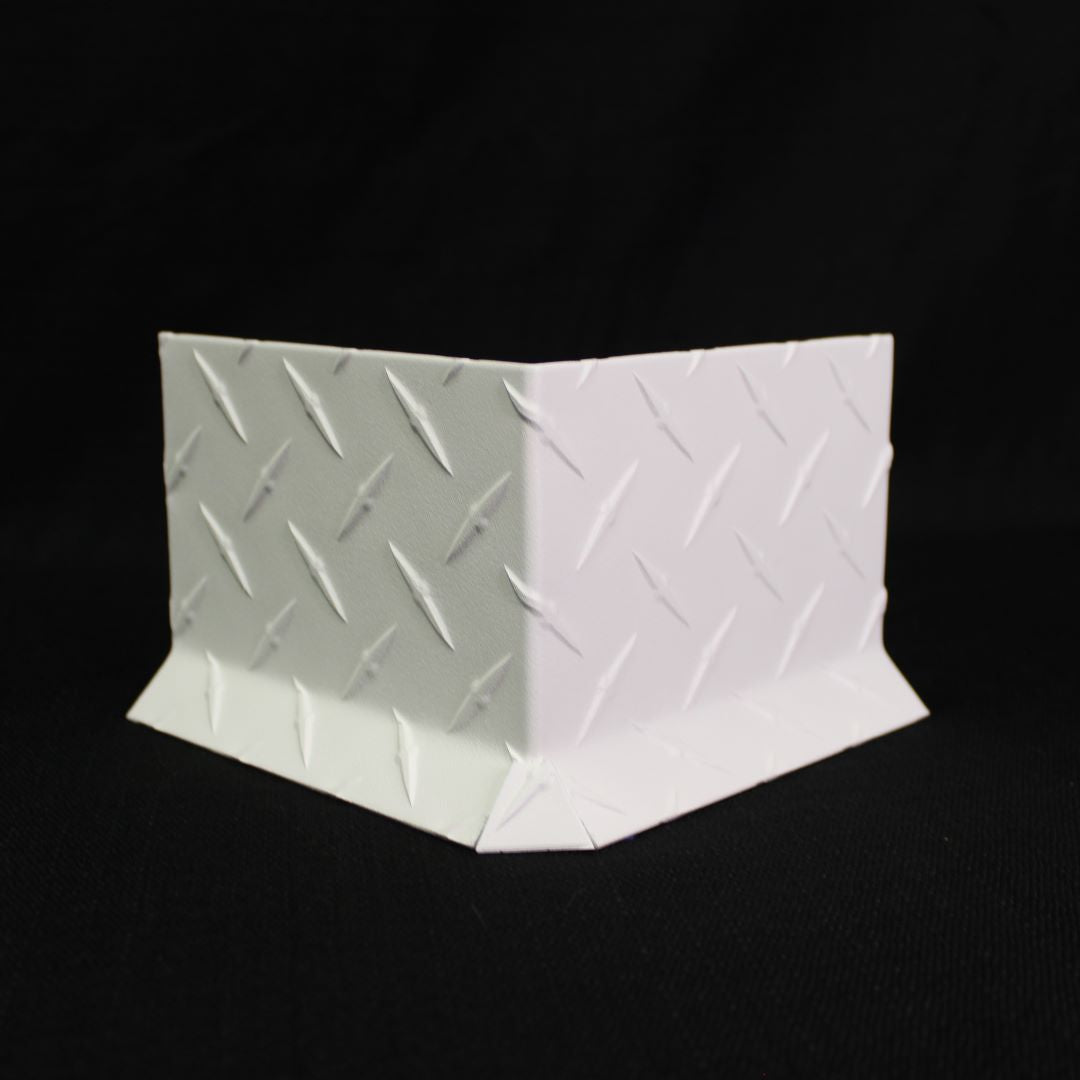

Provides Full Corner Coverage

10" total length (5" per side) provides substantial outside corner coverage.

Matches Standard Baseboards

Available in 4" or 6" heights to match standard baseboard sizes.

Customize Your Aesthetic

Polished Aluminum, Powder Coated Black, Grey, Red, and Blue options.

Choose Your Finish

Choose durable Diamond Plate for a rugged look or sleek Smooth Plate.

Built for Durability

Crafted from 0.063" thick 3003 aluminum alloy for impact and corrosion resistance.

Seamless, No-Screw Install

Integrated triangle tab ensures strong, seamless installation with construction adhesive.

Made in the USA

Proudly manufactured in Gallitzin, PA with attention to quality.

Commercial & Residential Use

Ideal protection for baseboard corners in commercial, industrial, and residential settings.

Secure your Tread-Ware with these stainless steel screws. An easy way to secure your parts and ke...

Secure your Tread-Ware with these stainless steel pan head screws. An easy way to secure your par...

Make installation easy with these fast holding adhesives. These construction grade adhesives, wor...

See how our outside corner baseboard molding adds a durable, professional finish. This video shows installation tips for commercial and residential spaces.

How do you cut this molding for an outside corner?

For a standard 90-degree corner, set your miter saw to a 45-degree angle. Place the molding on the saw (typically bottom face against the fence) and make your cut. Cut the adjoining piece at the opposite 45-degree angle. Always use a blade designed for non-ferrous metals.

How does the adhesive triangle tab work?

The integrated triangle tab sits behind the molding, providing a large, flat surface area for the construction adhesive (sold separately) to bond to the wall. This creates a very strong bond without any visible screws, resulting in a clean, seamless look.

Why do you use 3003 aluminum for this molding?

We use 3003 aluminum alloy because it offers the perfect combination of moderate strength, excellent formability (for the 90-degree bend), and high corrosion resistance. This makes it ideal for a long-lasting, durable finish in high-traffic or damp areas.

Can I install this over my existing baseboards?

This product is designed to be the baseboard corner itself, fitting from the floor up to its 4" or 6" height. It is not typically designed to fit *over* existing wood or MDF baseboards, but rather to meet up with them or be used as the complete baseboard system.

Do you offer bulk pricing for contractors?

Yes, we offer bulk pricing and commercial-grade solutions for contractors, installers, and B2B clients. Please contact our sales team at info@tread-ware.com for a quote on your project.

10" total length (5" per leg) for seamless, protective outside corner transitions.

Available in 4" or 6" tall options to match standard baseboard dimensions.

Choose Diamond Plate for a rugged look or Smooth Plate for a modern aesthetic.

$21.55